A Fresh Look & Consistent Availability

Landcross offers different types of technical veneers in a wide variety of species. We also combine wood veneer with other materials like metal. Our proprietary production process gives customers far more choices than can be found elsewhere, so manufacturers and designers are able to create the differentiated products that get noticed. Customers benefit from the consistent availability, easy procurement and predictable economics of Landcross’s technical veneers.

What We Offer

Landcross Vinterio

Landcross Vinterio technical veneer is made from hardwood lumber components and exhibits a solid, plank-effect look.

- Vinterio Stratus is made from one wood species.

- Vinterio Nimbus is made from two or more wood species.

- Nimbus Metal includes thin metal stripes in the veneer.

Component width is either 18-23 mm or 8-13 mm

Landcross Vinterio comes in sheets with fixed dimensions; custom dimensions can be produced by request.

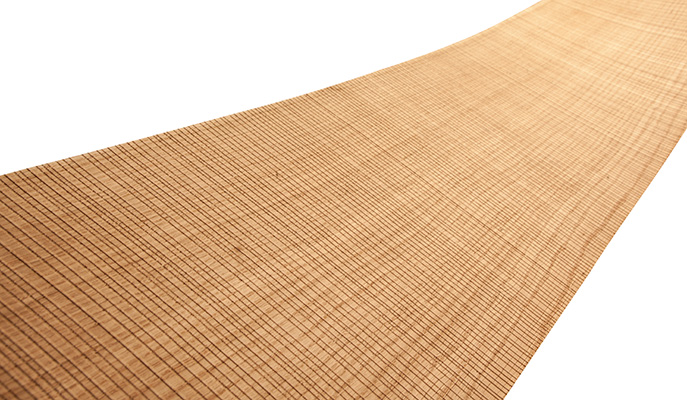

Landcross Linea

Landcross Linea technical veneer exhibits a linear, rift-type look. Unlike producers of reconstituted or man-made veneers, we use only the respective species; we do not bleach or color to artificially imitate other species. Landcross Linea shows – like all natural veneers – depth and light reflections from the wood grain.

The product comes in sheets with fixed dimensions; custom dimensions can be produced by request.

Landcross Linea is available in large volumes with short lead-times.

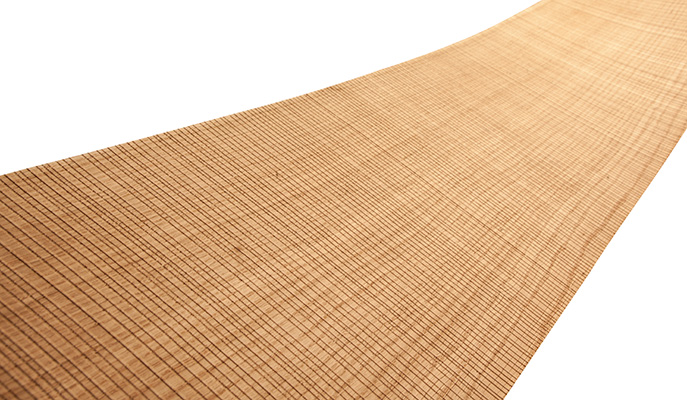

Landcross Linea

Landcross Linea technical veneer exhibits a linear, rift-type look. Unlike producers of reconstituted or man-made veneers, we use only the respective species; we do not bleach or color to artificially imitate other species. Landcross Linea shows – like all natural veneers – depth and light reflections from the wood grain.

The product comes in sheets with fixed dimensions; custom dimensions can be produced by request.

Landcross Linea is available in large volumes with short lead-times.

Landcross Freeform

Metal inlays add distinction to wood surfaces. Historically, using them has involved costly manual labor or limited the shapes to simple linear designs. Landcross’s new and unique industrial process produces veneer featuring almost any organically shaped inlay. Ornaments, messages or logos can be added to wood surfaces quickly and at reasonable cost. The inlays enhance the veneer’s appearance, add functionality and carry a brand message if desired.

Landcross Freeform technology can be used with most Landcross veneers. The specified product is unique to each customer, designed to customer specifications and produced to-order. Our standard Inlay material is aluminum or copper – other materials are available by request.

Other technical or treated veneers

Landcross adds value to natural veneers by modifying their appearance or surface quality. Key varieties include:

Landcross Figura: A technically figured veneer that we can produce in large volumes and with consistent quality. Key species: Anigré and European Sycamore

Rough cut: Like raw, freshly sawn lumber, the veneer has a slightly rough surface allowing for rustic, relaxed designs. Key species: European Oak, Larch and American Walnut

Amber Beech: A new all-natural process that allows us to offer widely available European Beech in a beautiful, darker-than-usual golden brownish tone.

Vintage Style: With our all-natural, accelerated aging process, beautiful vintage wood is now available in industrial dimensions and quantities. Key species: European Oak

Other technical or treated veneers

Landcross adds value to natural veneers by modifying their appearance or surface quality. Key varieties include:

Landcross Figura: A technically figured veneer that we can produce in large volumes and with consistent quality. Key species: Anigré and European Sycamore

Rough cut: Like raw, freshly sawn lumber, the veneer has a slightly rough surface allowing for rustic, relaxed designs. Key species: European Oak, Larch and American Walnut

Amber Beech: A new all-natural process that allows us to offer widely available European Beech in a beautiful, darker-than-usual golden brownish tone.

Vintage Style: With our all-natural, accelerated aging process, beautiful vintage wood is now available in industrial dimensions and quantities. Key species: European Oak

Why Buy From Landcross?

A fresh look

For centuries, only five basic veneer cuts have been available: Flat, half-round, quarter, rift and rotary-cut. With the advent of Landcross’s technical veneers, the ability to create a vast variety of fresh looks is now possible.

What you see is what you get

Landcross products use only the real species to create new looks. No color is added to artificially imitate other natural wood species: Walnut is Walnut, Oak is Oak. Landcross technical veneers have the visual qualities and physical characteristics of the wood species used.

Superior quality

Landcross’s technical and value-added veneers are produced on the same best-in-class machines as Landcross’s traditional veneers. Our professional production and quality management processes guarantee the highest quality product at all times.

Reliability

For three generations Landcross has been the partner customers worldwide count on. Because of the large volumes we produce, products that are procured today will be available in the future to re-order, and mix or match. Our order and delivery processes exceed the highest professional standards.

Certified products

Most Landcross technical veneers are FSC® or PEFC™ certified, so you are assured what you buy is from sustainable sources.

A Health Product Declaration™ (HPD) for Landcross Vinterio and Landcross Linea ranges of sliced wood surfaces ensure that Landcross technical veneer products can be used safely.

Reliability

For three generations Landcross has been the partner customers worldwide count on. Because of the large volumes we produce, products that are procured today will be available in the future to re-order, and mix or match. Our order and delivery processes exceed the highest professional standards.

Certified products

Most Landcross technical veneers are FSC® or PEFC™ certified, so you are assured what you buy is from sustainable sources.

A Health Product Declaration™ (HPD) for Landcross Vinterio and Landcross Linea ranges of sliced wood surfaces ensure that Landcross technical veneer products can be used safely.

How Do You Benefit?

Differentiation

Landcross’s technology and processes allow you to create the new looks that differentiate your products in the marketplace. This is especially true when customers opt to combine different wood species and materials to their specifications. The resulting differentiation leads to more recognition, more demand—and more sales.

Saving time

Landcross’s technical veneers are known for their consistent availability, and consistent quality. Once specified, procurement of material consumes considerably less time than procuring naturally grown veneers.

Predictable economics

Many of Landcross’s technical veneers come in a variety of fixed dimensions, and dimensions can be produced to customer-specific specifications as well. The availability to order veneers to fit your needs results in less waste and higher yields for our manufacturing customers.

Lower working capital needs

The continuous availability of Landcross’s technical veneers reduces the need for customers to stock them, thereby reducing working capital needed.

Predictable economics

Many of Landcross’s technical veneers come in a variety of fixed dimensions, and dimensions can be produced to customer-specific specifications as well. The availability to order veneers to fit your needs results in less waste and higher yields for our manufacturing customers.

Lower working capital needs

The continuous availability of Landcross’s technical veneers reduces the need for customers to stock them, thereby reducing working capital needed.